Your Partners

in Progress

years

SQM Land Area

Welded Assemblies

Forward Thinking

Future Focused

Our continued investment in new technology is pushing us towards greater heights.

Advantage Mehta Automotive

Why Us?

Mehta Automotive has robust in-house capabilities, including an advanced ERP system that streamlines operations for greater efficiency and accuracy. With in-house tool development and comprehensive manufacturing under one roof, they ensure quality control at every stage of production. Mehta Automotive's extensive product development experience translates to well-engineered, reliable products tailored to meet diverse automotive needs, making them a trusted partner for innovative and

high-performance automotive solutions.

Advanced In-House ERP System

Our in-house developed ERP system provides our customers with real-time visibility into the production process, stock levels, and dispatch status. This system enhances transparency and allows for seamless process planning by displaying live updates on production and quality. As a result, we can respond quickly to customer inquiries, ensuring efficient and timely communication. Learn More

In-House Tool Development

We take pride in having a complete in-house setup for designing, manufacturing, and testing all necessary tools, jigs, fixtures, and gauges required for production. Our highly skilled technical team, combined with cutting-edge tool-making facilities, enables us to produce high-quality tools in minimal time, ensuring precision and maintaining strict quality standards. Learn More

Comprehensive In-House Manufacturing

From pressing and fabrication to painting, all our production processes are carried out in-house. This allows us to maintain strict control over the quality of our products and ensure timely delivery to our customers, without the delays and uncertainties associated with relying on external vendors. Learn More

Extensive Product Development Experience

With years of expertise in manufacturing Sheet Metal Stampings, Welded Assemblies, Tubular Parts, Machined Forgings, and Painting, our experienced team understands the evolving needs of our customers. We are equipped to develop a wide variety of products under one roof, meeting the ever-changing demands of the industry. Learn More

Our Strengths

WHY CHOOSE US?

High Quality Parts made on State of Art Machines

Fast product development

(in-house tool designing and manufacturing)

On Time Delivery.

STATE OF ART MACHINES

(POWERED BY INDUSTRY 4.0)

IN-HOUSE TOOL DESIGN AND MANUFACTURING

(FAST PRODUCT DEVELOPMENT)

HIGHLY SKILLED TECHNICAL MANPOWER

(FIRST TIME RIGHT)

IN-HOUSE DEVELOPED ERP SYSTEM

(ON TIME DELIVERY, EVERYTIME)

SINGLE POINT CONTACT

(QUICK RESPONSE TO CUSTOMER)

DEDICATED LOGISTIC PARTNERS

(ON TIME DELIVERY)

Our Strengths

WHY CHOOSE US?

State of Art Machines

Powered by Industry 4.0

Highly Skilled Technical Manpower

First time right

Single Point Contact

Quick response to customer

In-House tool design and manufacturing

Fast product development

In-House Developed ERP System

On time delivery, Everytime

Dedicated Logistic Partners

On time delivery

Quick response to Customer concerns

Dedicated customer representative

(single window)

Highly skilled and dedicated manpower

Our Infrastructure

Growth with technology

Our continued investment in new technology is pushing us towards greater heights.

Our Products

Consistent Quality Products

Our customers have benefitted from our years of experience and diverse portfolio

Our Infrastructure

Growth with technology

Our continued investment in new technology is pushing us towards greater heights.

Parts Made For

Employee Benefits

Worker

Welfare

Mehta Automotive is dedicated to worker welfare, prioritizing comprehensive safety measures, including rigorous fire safety protocols and proactive risk management. The company also provides ongoing medical support, ensuring a healthy, secure work environment where employees feel protected and valued.

Commitment to Safety

Fire Safety Training

Health Checkup

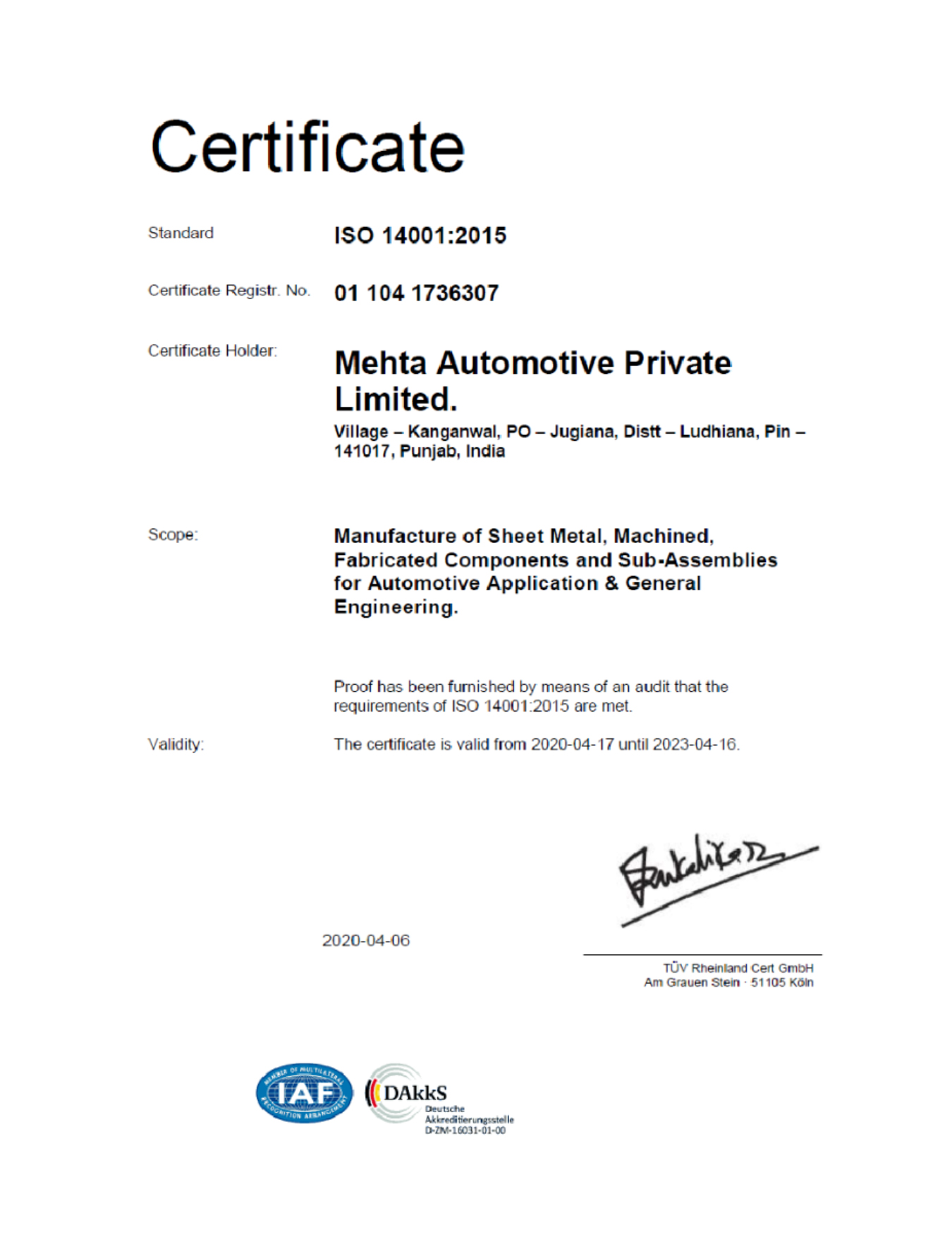

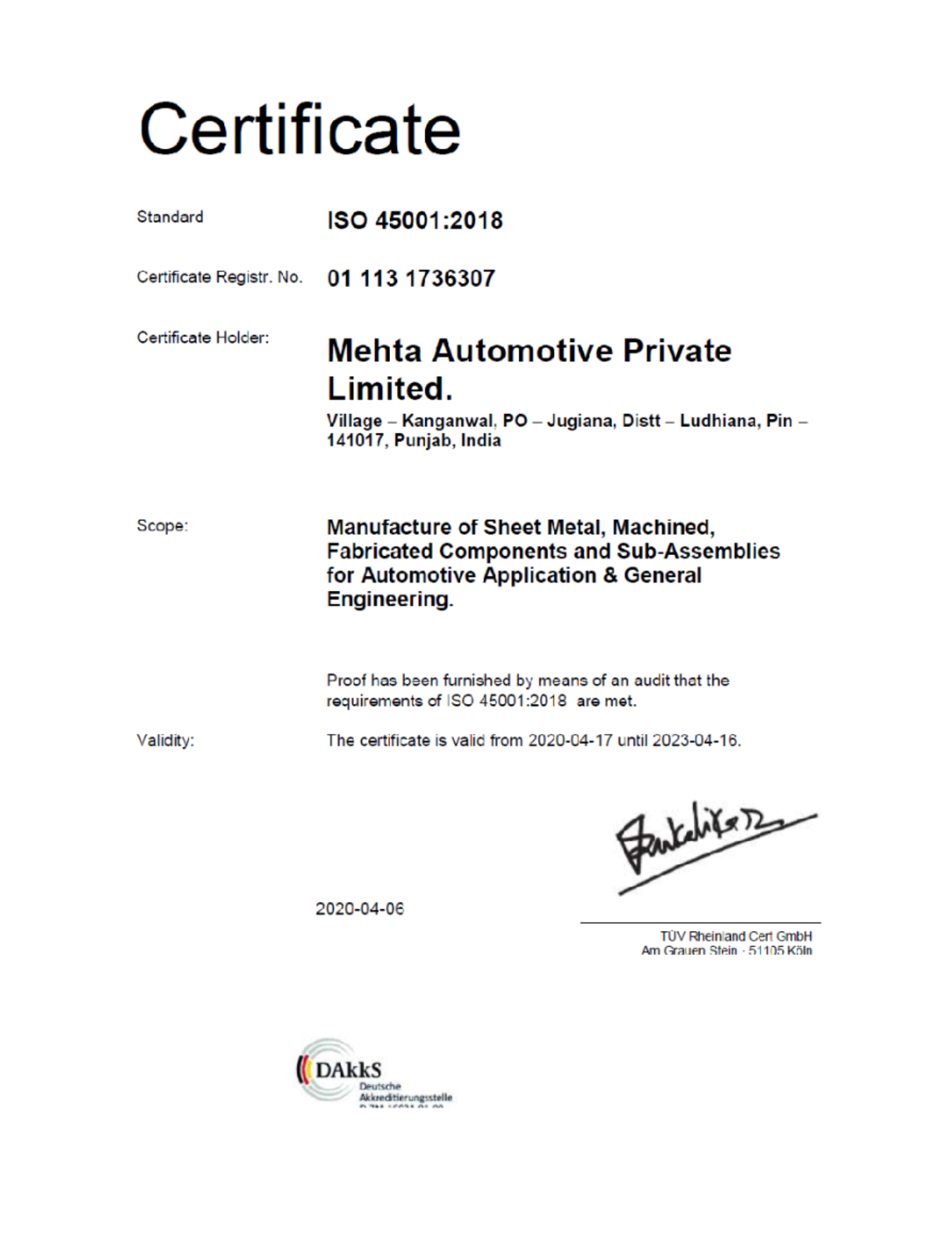

Certifications

MILESTONES

2017

SQ mark Certification

by Hyundai

2018

Production facility expanded with new buildings

2019

Certified Green Supplier by Maruti Suzuki

2005

Company

Started

2007

Robotic

Welding

2008

Automotive

components

2008

TS 16949

ISO 14001, 18001

2013

Fully automatic

CED plant operational

Blogs

How AI is Changing Our Daily Life and Helping Us Work Smarter

Artificial Intelligence (AI) is no longer just a topic for big tech companies—it is becoming part of our daily life in India. From using mobile payment apps to getting product re

Work Management in a Manufacturing Company: Simple Steps for Success

Work Management in a Manufacturing Company: Simple Steps for Success In a manufacturing company, many things happen at the same time. There are orders to finish, machines to run, q

Healthcare & Medical Support

At Mehta Automotive, we care deeply about the health of our employees. We regularly organize medical camps that provide free check-ups and health consultations, ensuring that our t

Location

Subscribe now

Get the latest news & updates

Drop us a line

ASK US HOW?

Save MILLIONS every year in your purchasing.